Purpose

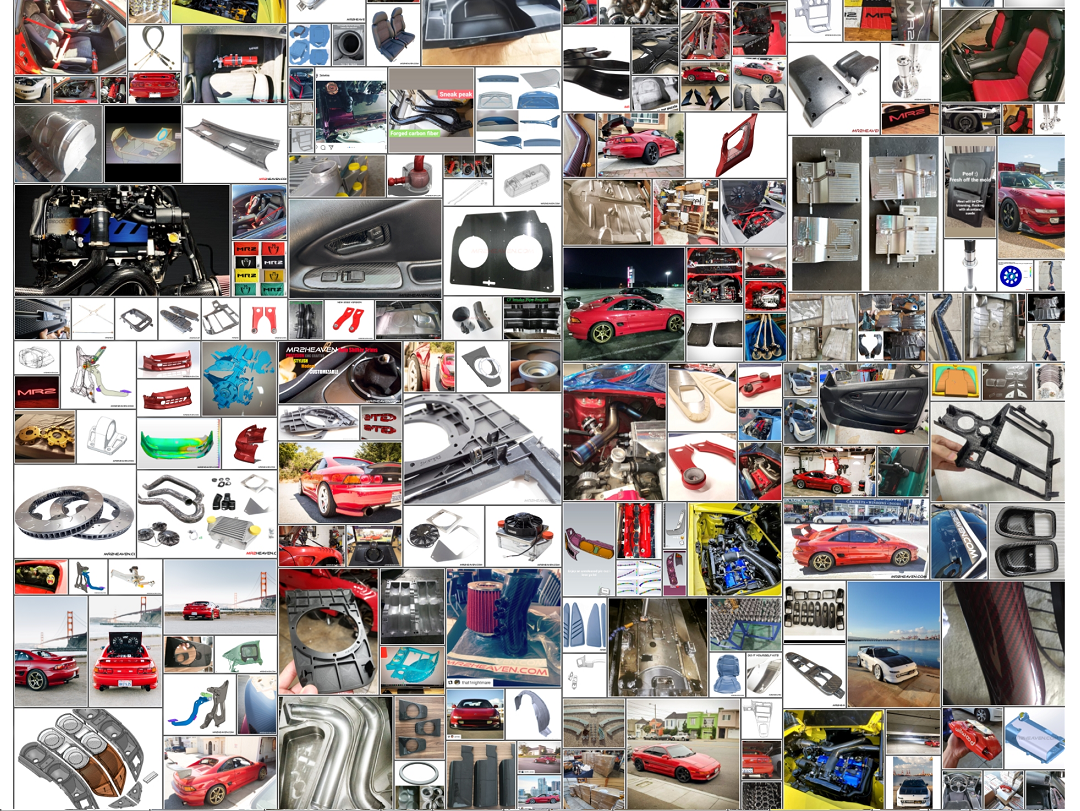

We went all out on these trims to leave a lasting legacy, something we can be proud of and as proof of concept & technical prowess for our future endeavors. High amounts of details and complex curves are usually very difficult to achieve with carbon fiber but on our trims, they come out stunning, beautiful, accurate, lightweight and sturdy. We aimed to create the highest quality carbon pieces that one can, utilized state of the art manufacturing methods and equipment with no shortcuts taken, similar to what goes onto very expensive satellites and expensive supercars/F1. The end result is a stunning work of art tethering on the edge of technology and what is possible.

Exceptional - One of A Kind

These aren't your typical cheap CF trims produced from inverted hand made fiberglass molds and vacuum bags in the garage, or "sticker" type overlays with 3M tape, or carbon fiber layer skinned over the original plastic trims. These trims are full carbon fiber replacements, no original parts/plastic cores are needed. That means no budging, constipated looking surface finish, air bubbles and poor fitment that often comes with skinning over original parts.

How It's Made

To create and form these complex and highly detailed full carbon fiber trims a reality, pre-preg/dry carbon production method is used and is a requirement. The original trims first were 3D scanned up to 0.02-0.05mm accuracy and CADed for the best fit and accuracy possible.

Next, CNC aluminum molds are designed and utilized. Pre-infused carbon layers are applied skillfully to aluminum molds and completely cured under varying high pressures and heat in a massive autoclave undergoing numerous different stages over many hours.

Rare & Beautiful

This extensive and expensive production process ensures complete curing of the part with the best quality possible to the highest of standards which cannot be matched with the lather wet carbon fiber part production method. These trims exude beauty, class, and a high-end, exotic appeal. They embody sportiness and loyalty to the original design, featuring cutting-edge technology, exceptional accuracy, and high performance, delivering simply jaw-dropping amusement.

You'll be hard pressed to find similar full carbon replacement trims for other platforms. Even modern BMWs, Audis, Porsches, Mercedes Benz, from OE and aftermarket companies alike rarely have any interior trim comparatives of this caliber, unless it is on their dedicated expensive race cars. For comparatives, look closer to half million dollar Ferraris, F1, Paganis and multi million dollar hypercars to find trims of this caliber.

Have your friends hold the extremely lightweight pieces and watch their expression turn to awe, resemble as if they just witnessed a miracle. -As if the lightweight and strength aspect of the pieces alone when considering the actual size and dimensions of the part almost defies physics and is out of this world.

We plan to keep limited quantities on hand due to high costs necessary to procure each piece. Only 1 of each variant is able to be produced every 1-2 days, or around 10-15 pcs a month.

FEATURES

- Made with full Pre-Preg/Dry Carbon Fiber

- Crafted out of special Aluminum molds/Autoclave cured under high heat and pressure in numerous different stages over many hours for the highest performance and quality possible

- Durable Nylon plastic mounting clips are epoxied on. Some small intrinsic details are molded/integrated with the numerous carbon layers for high durability and some areas are CNCed milled.

- Extremely lightweight. Some smaller trims like the door cup cover are similar to a piece of paper in weight at around 0.6oz. Our window switch cover is around 1.8oz.

- All functions and components install on and work as OEM intended.

- Full plug and play, no modifications needed

FITMENT

- 1991-1998 Toyota MR2. Please pay attention if your car is LHD (Left hand drive) or RHD (Right hand drive). Some trims will only work for one and not the other!

NOTES

- These trims are all meticulously hand crafted and as such, no single trim is identical to another and each trim is unique.

MR2 Experts - 20+ years of experience.

Largest MR2 Parts Collection in the World

Have ideas, need something, have suggestions or questions? Hit us up!

Sales@MR2Heaven.com

MR2Heaven

Since 2002, we've been working to improve almost every aspect of the Toyota MR2, whether it's restoring it to its former glory or increasing its performance, efficiency, or style.

Our team of experts offers a wide range of OEM and aftermarket parts, as well as our own unique designs and engineering that can't be found anywhere else. We're dedicated to providing the best products at great everyday low prices and supporting the Toyota MR2 community with high-quality products.

If you have any new ideas, let us know – we're always looking for ways to bring your vision to life. Thank you for choosing MR2Heaven for all your Toyota MR2 needs.