Inventory Status 2/28/2026

Phasing Out:

- Frunk Plastic U Panel (Lost of all molds and manufacture due to fire)

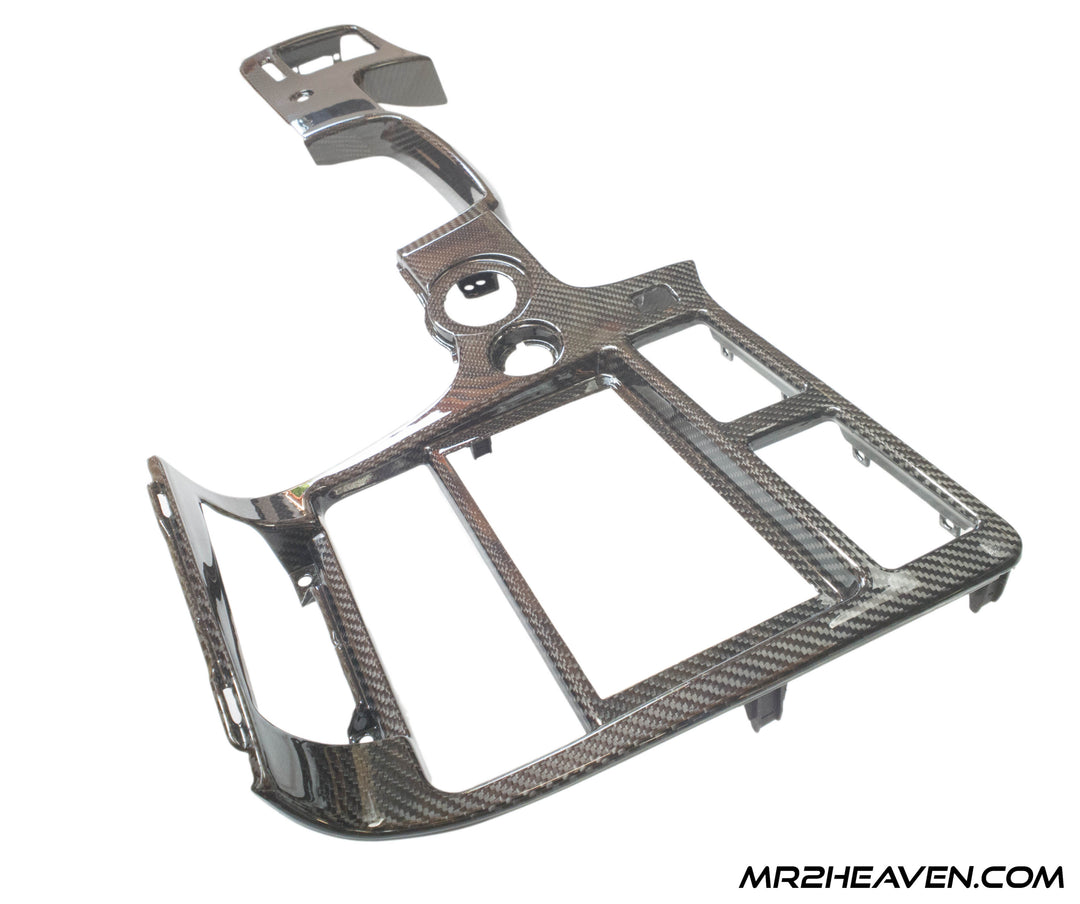

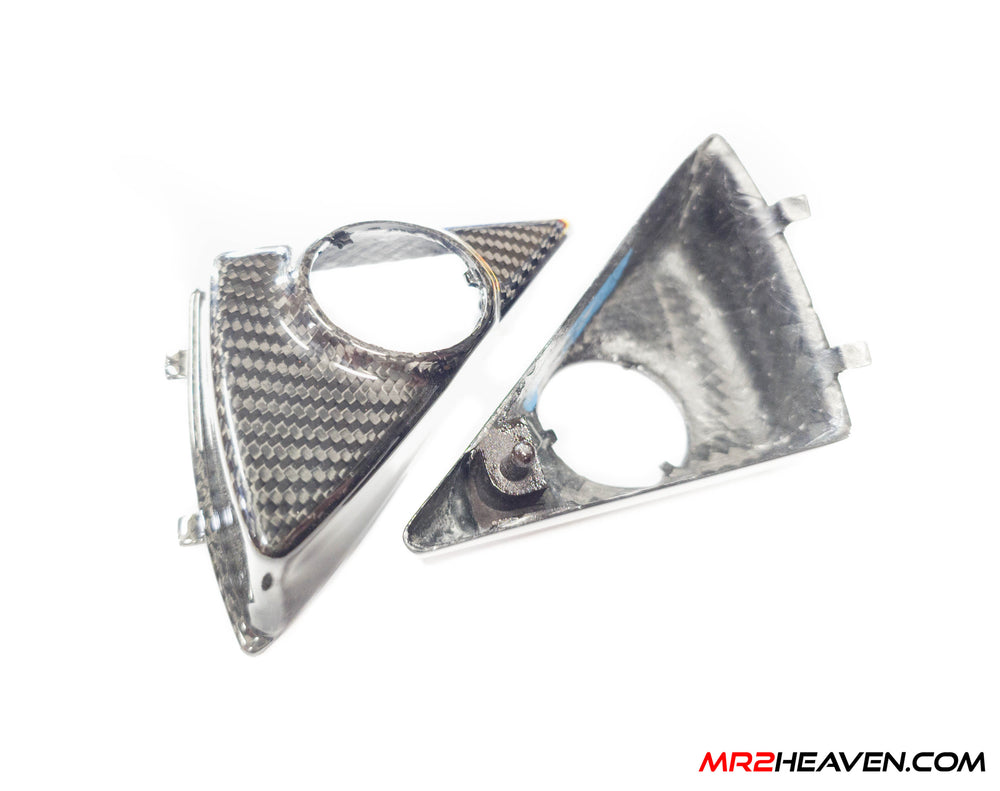

- Halo Trim (B&M Variant) in Plastic (Only have CF versions left)

- Lightsup Pro Sequential Corner Lights - Currently only White Amber Available

- Midship Dandism Decals (some variants)

- Spring Activated Cup Holders

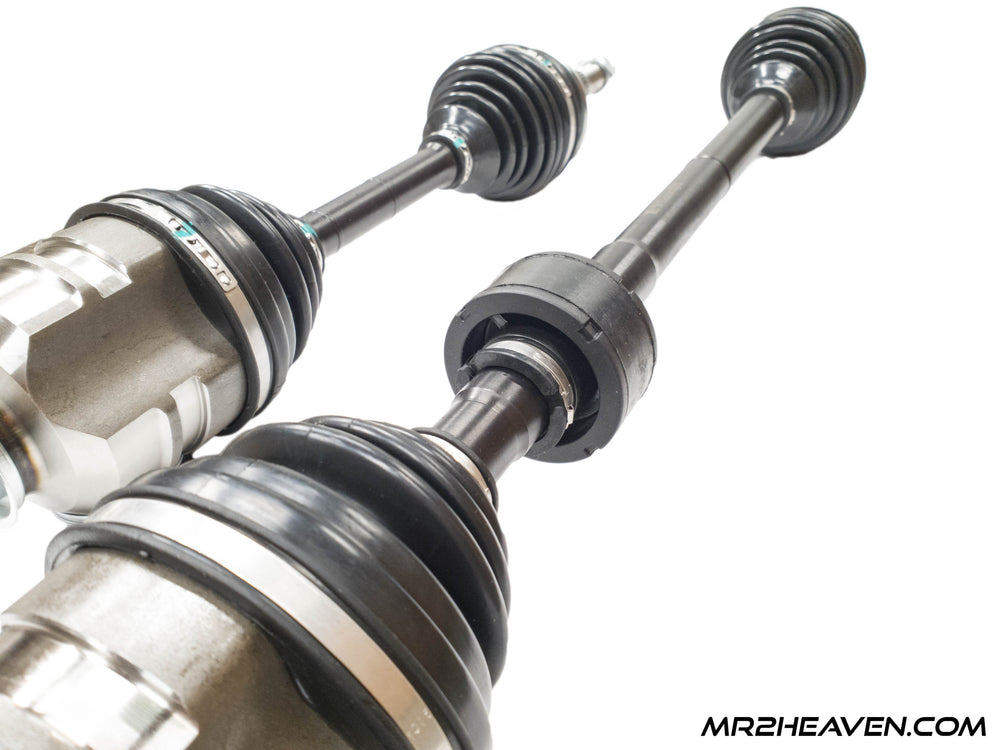

- 300M Axle stubs

Out/Low in stock (Not Comprehensive):

- Twin Cam 16 Sticker in Black/Gray

- V2.1 Solid Fender Delete Moldings (V2.0 in stock) - ETA March 2026

- AW11 C Visor Trim in CF - ETA Q1 2026 - 1/27 - ETA May/June 2026

- AW11 Front Radiator Top Panel - ETA Q1 2026 - 1/27 - ETA May/June 2026

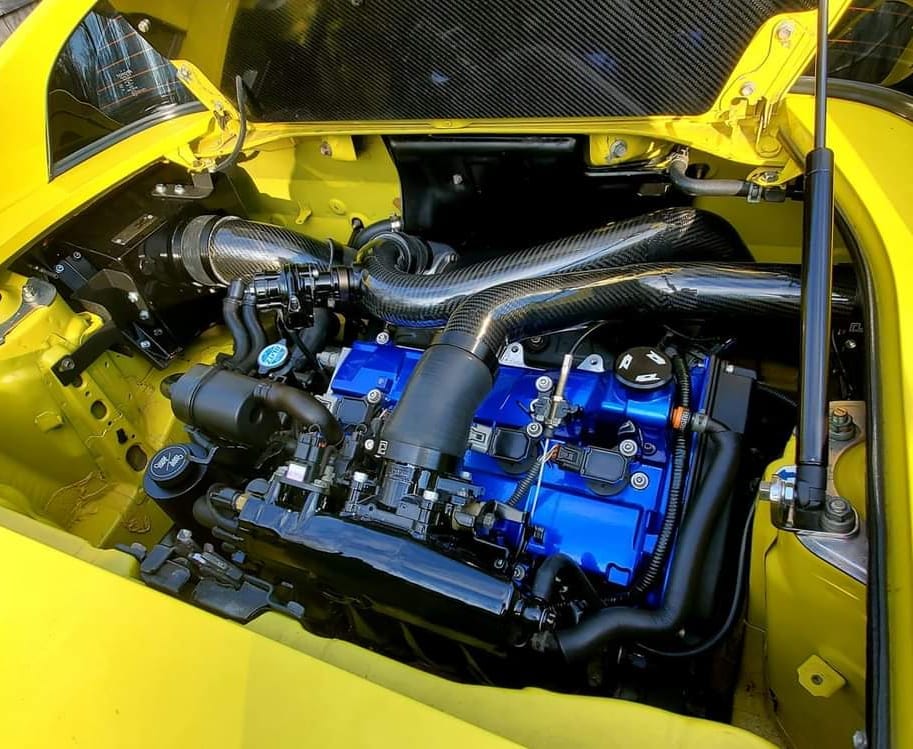

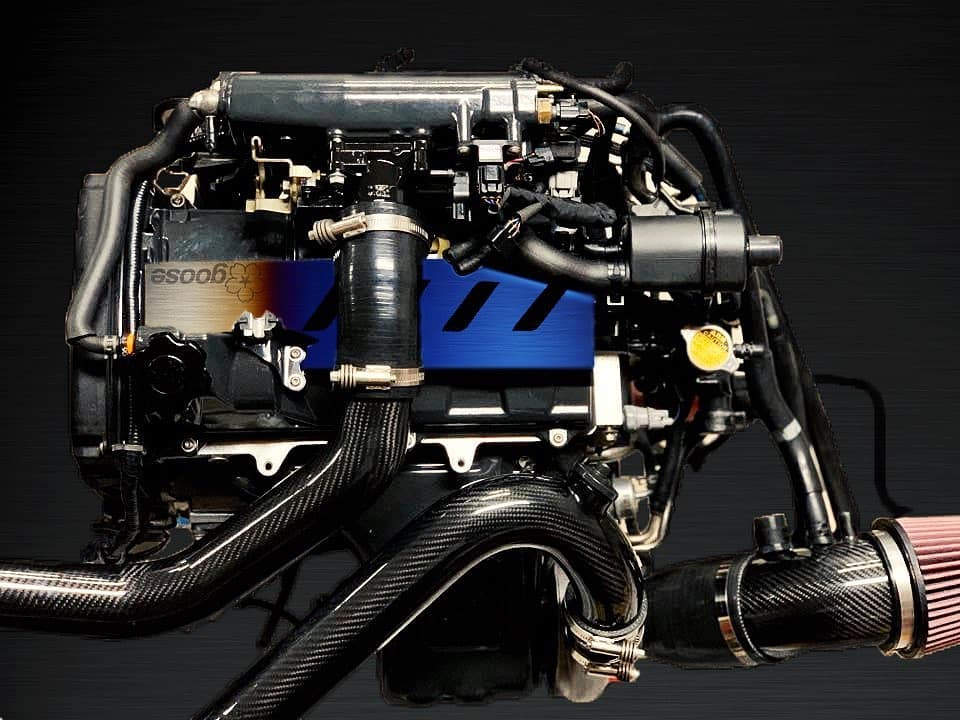

- Stainless Steel Intercooler Pipes for GEN2/3/5 (GEN4 SS and CF versions available) - ETA March 2026

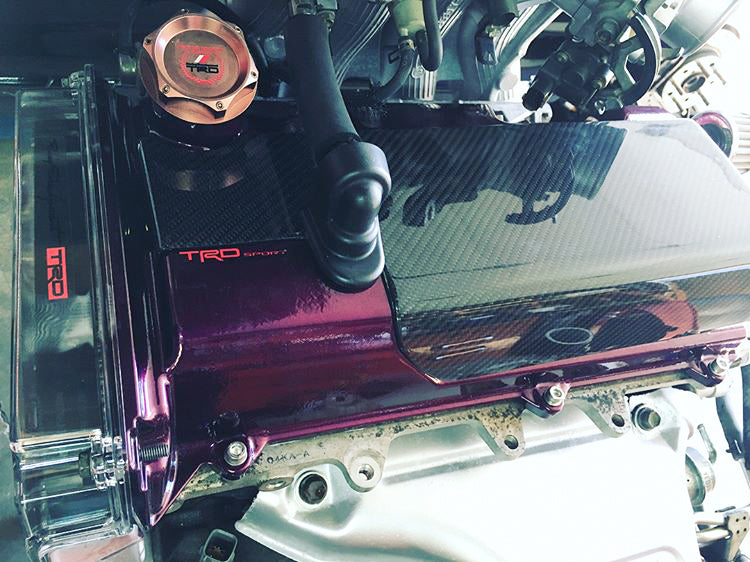

- Turbo Engine Lids SW20 - 2FG/3CF/0DryCF (ETA May/June 2026)

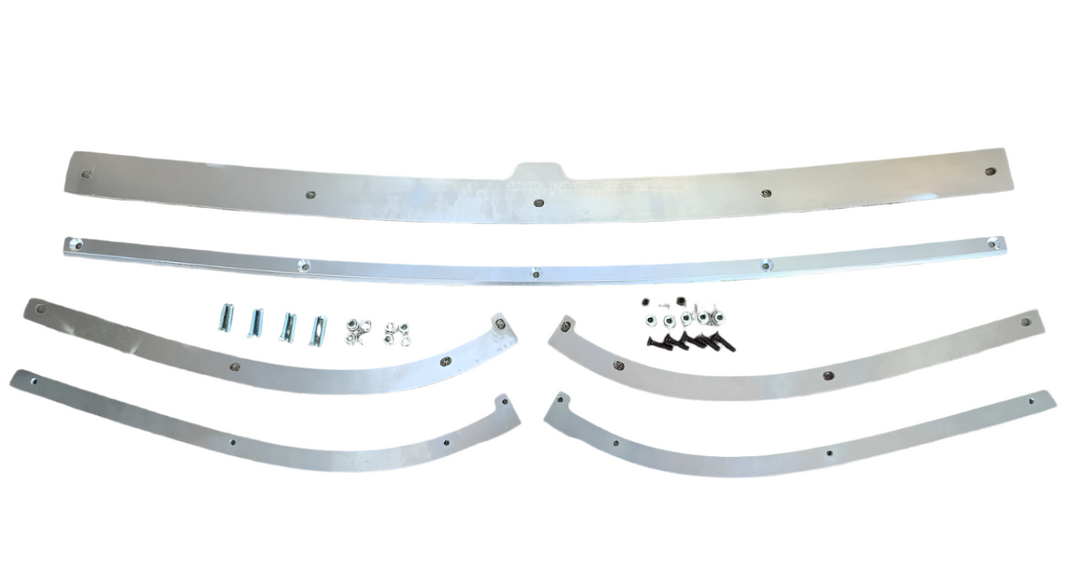

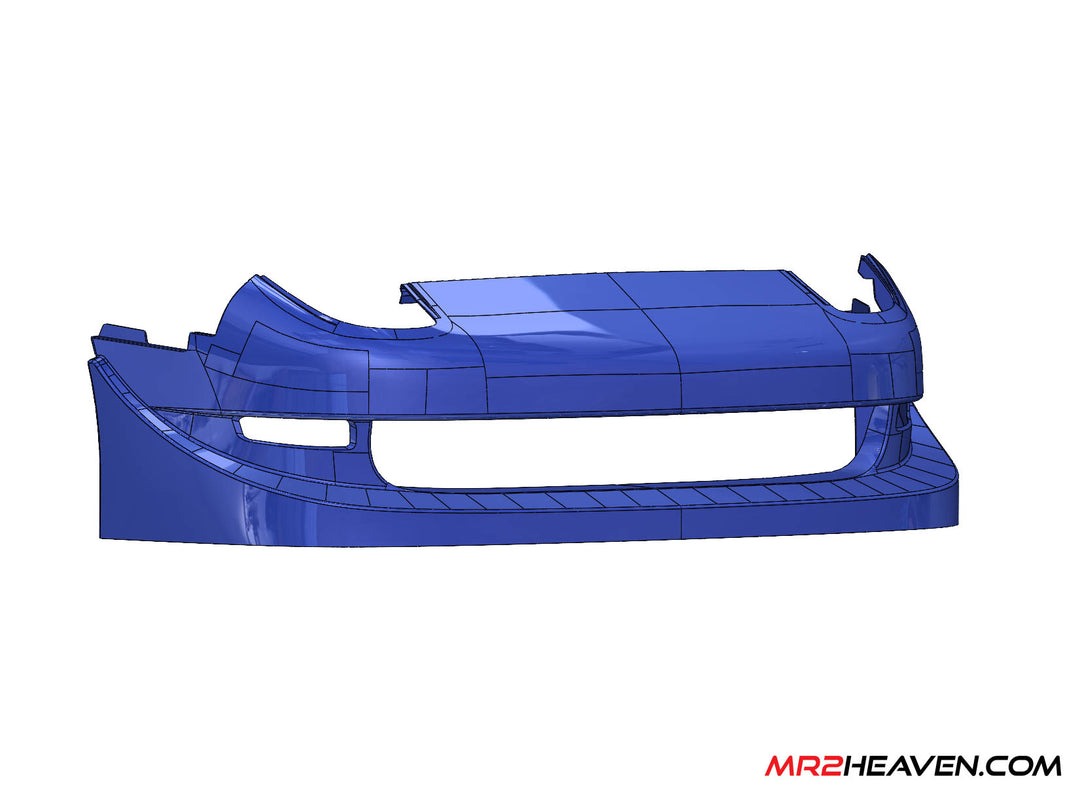

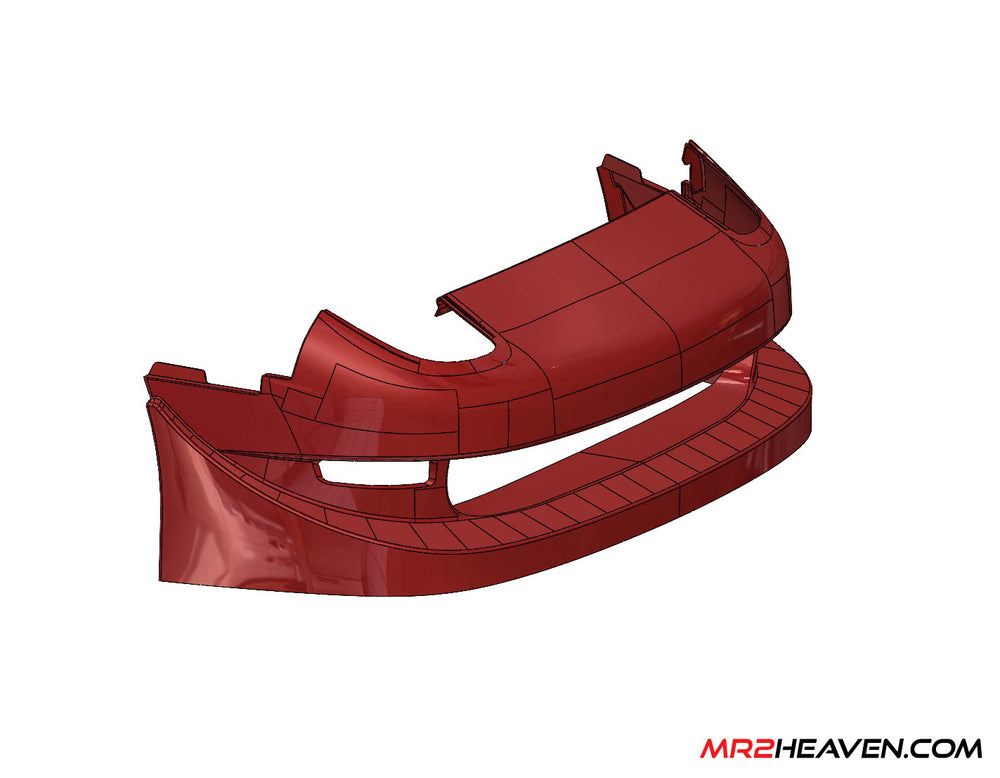

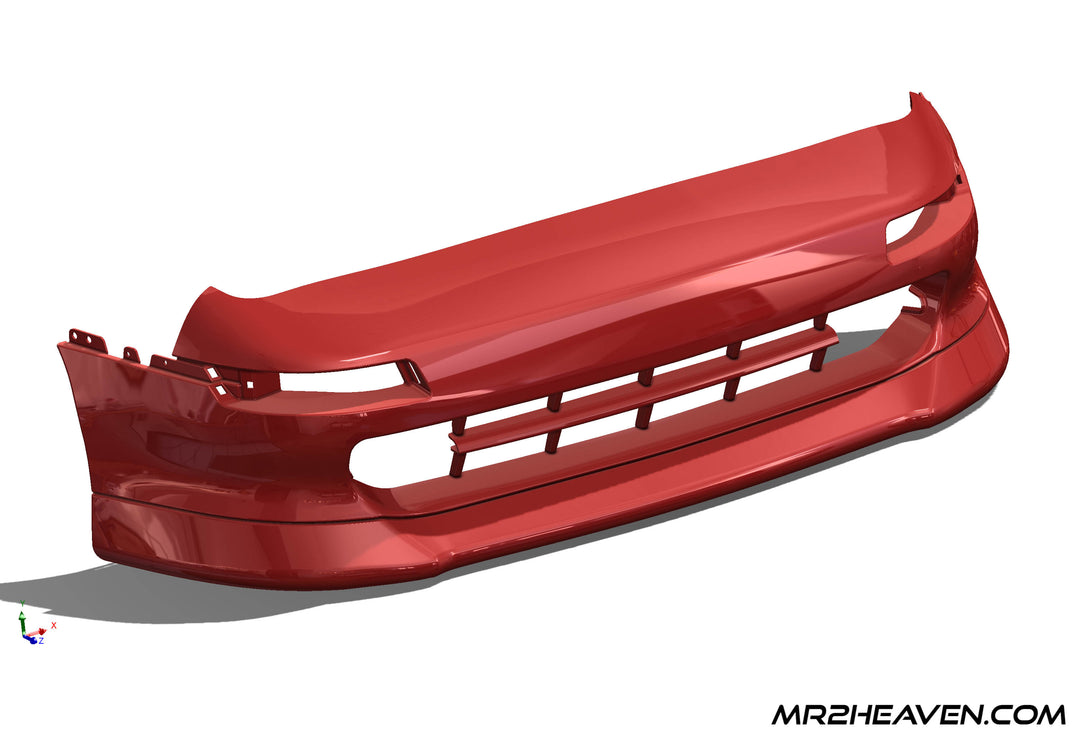

- Aeroware Style Front Lip - 1 FG (ETA May/June 2026)

- Holy Style Front Lip - 3 CF (ETA May/June 2026)

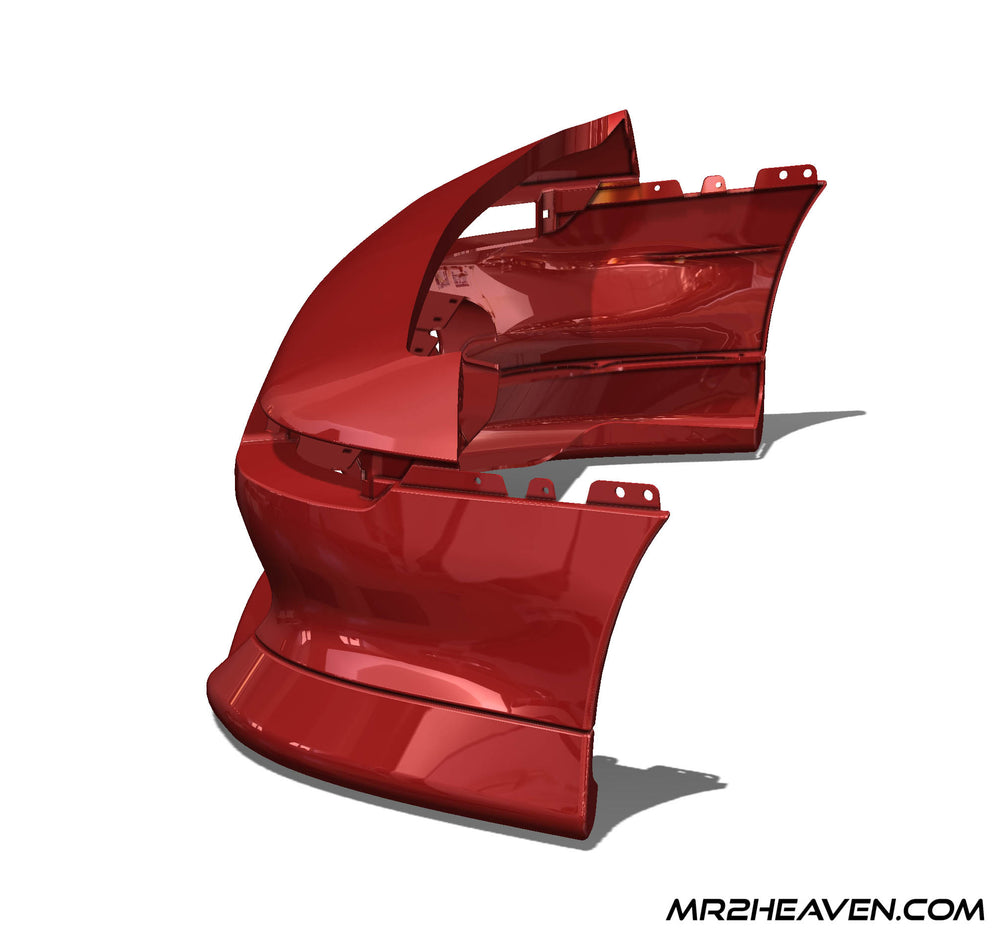

- Border Style Fenders - 2 CF (ETA May/June 2026)

- MADPSI Style Fenders - 3CF (ETA May/June 2026)

- Phoenix Power Style Engine Lid - 3CF (ETA May/June 2026)

- Greddy Style Spoiler - 2CF (ETA May/June 2026)

- Greddy Style Side Skirts 0CF (FG available) (ETA May/June 2026)

- V2.0 V Mount Dry Carbon Race Spoiler - 2CF (ETA May/June 2026)

- V-Mount Race Spoiler Wing stands - 0 - 1/27 - ETA May/June 2026

- 0 CF Kouki Tail light Center Panels - ETA April 2026