We ship worldwide! 🌍 ❤️️

- Home

- ⚡Kouki Tail Lights

- ❤️ MR2Heaven Products

-

❤️ MR2 SW20 (1991-1998)

- ❤️ MR2Heaven Products (All products we make)

- ** The Essentials

- ** New Products

- ** Bundle Deals

- **Body Kits & Aerodynamics

- ** Carbon Fiber

- ** Kouki Tail Lights

- Apparel / Decals / Flags / MISC / Cool Stuff

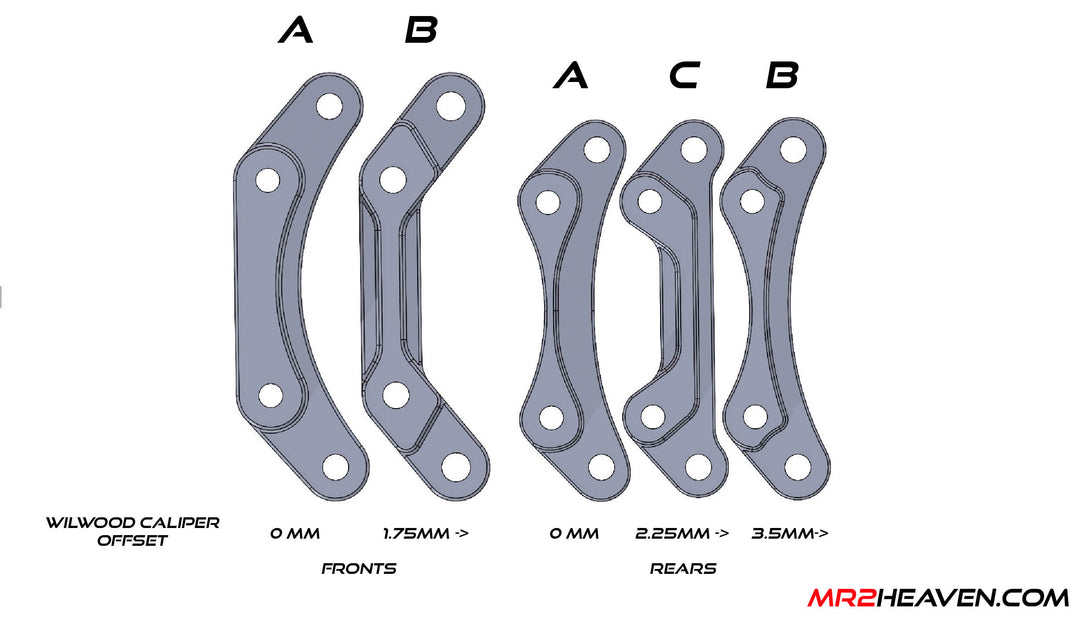

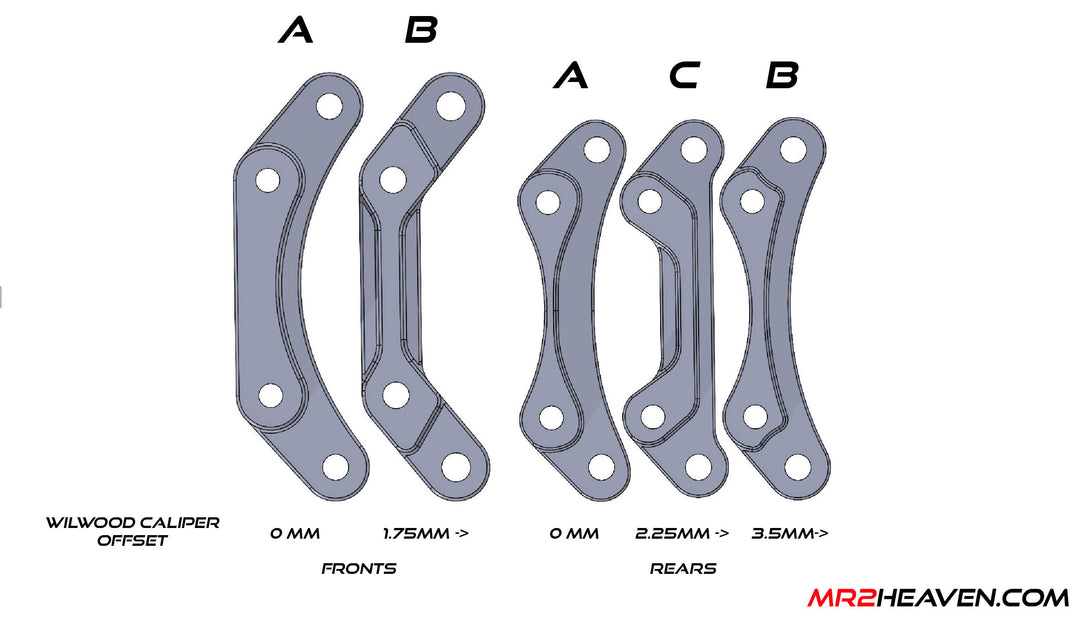

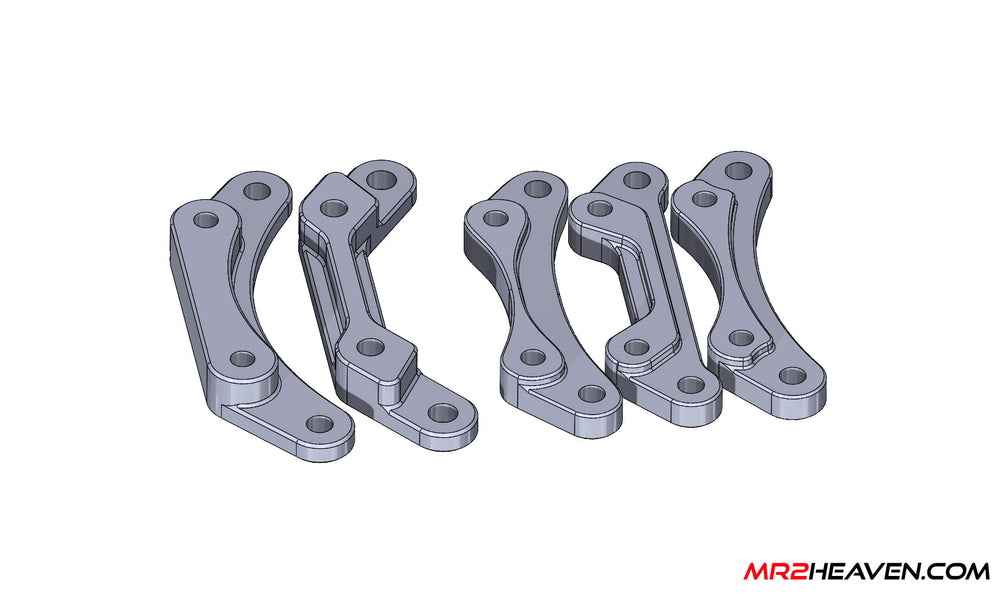

- Brakes / Big Brake Kits

- Cooling System

- Drivetrain / Transmission

- Electronics

- Engine

- Exterior / Chassis

- Fuel System

- GEN2 3SGTE Parts

- GEN3 3SGTE Parts

- GEN4 3SGTE Parts

- GEN5 3SGTE Parts

- Intakes

- Intercoolers / Misc Parts

- Interior Parts

- Suspension Parts

- Wheels / Tires / Accessories

- Used Parts / Scratch & Dent

- ❤️ MR2 AW11 (1985-1989)

- ❤️ MR2 ZZW30 (99-2007)

-

Other Makes

- Gallery

- Line Card

- Contact

Have Questions?

Fast Response - Our team is here to answer any questions or concerns you have, so don't hesitate to reach out

Email - Sales@MR2Heaven.com

VIP newsletter

Get notified of the latest developments, special offers, restocks and once-in-a-lifetime deals.